UK Benchmarking Tour

Back to Training- Date: 5 Nov - 7 Nov 2024

- Time: 8:00 am to 5:00 pm

To register, please email kate@icbe.ie

Indicative Costs (subject to change depending on demand and pricing when we finalise reservations)

Maximum number of delegates will be 14 people.

ICBE Member fee €1050

Non- ICBE member fee €1320

(Based on 12 delegates – if we get 14 delegates, price will decrease to €900 / €1130)

Costs include 2 nights’ accommodation with B&B + Dinner and Bus transfers to/from each site and hotel.

Delegates are responsible for their own air travel costs and transfers from / to Airport.

ICBE Advanced Productivity Skillnet is running a Benchmarking Tour to the UK in November in association with Onsite Insights. We will get to see best practise in action at 3 world-class companies. No theory, no textbooks, just what works and why, direct from organisations that have achieved success.

Visiting leading companies can provide an organisation with valuable insights, networking opportunities, benchmarking, employee development, and inspiration for innovation, all of which can contribute to their success in the long run.

The 3 companies are :

Cummins is a world leader in the design and manufacture of engines and power generation equipment, including PowerCommand standby and prime power systems. The site also provides single-source warranty, planned maintenance, and round-the-clock emergency service 24 hours a day, seven days a week including back-up power rental through our network of distributors.

At Daventry the plant manufactures automotive engines used in heavy and medium trucks, bus and off highway vehicles. The site also manufactures light duty automotive. More recently the site has also begun manufacture of the power generation systems (Gensets) which are used in a variety of environments including rail, mining, oil and gas and commercial marine.

Manufacturing processes on site include: Machining of blocks, Assembly build, Sub-assembly, Paint, Final Test.

Across the industrial design, manufacturing and maintenance worlds, RS Group are the digital destination for product and service solutions to help their customers with the maintenance, repair and operation of their businesses.

RS provide global access to an unrivalled range of over 750,000 stocked industrial products. Each day their team of experts deliver solutions to resolve our customer’s challenges across design, procurement, inventory and maintenance. They consistently strive to deliver the best possible service to all of their customers and challenge themselves to provide a seamless procurement experience.

RS Group have been on a CI journey for at least 15 years, starting by doing improvement projects (6-sigma) and over the last 3 years starting to move more into the Lean Thinking approach. They are in the process of getting the Executive Committee to sign off a new strategy which introduces the Shingo Approach as the way they want to work across the organisation.

Lear is the world leader in luxury and performance seating for the automotive industry. Supplying the majority of the world’s leading manufacturers, they have established a reputation for superior engineering, excellence in manufacturing and craftmanship. The organisation was named as one of the Fortune’s 2023 Most Admired Companies. Seating is built to order on a just in time basis and the site manages over 3000 product variations over 2 build lines. Redditch is an assembly plant and the sole supplier of seating for one of the UK’s most prodigious car brands.

The Redditch site was purchased by Lear in 2010 and they rapidly created a centre of excellence. Employee engagement is achieved through both their Kaizen initiative and also their TIC (Team Improvement Circle) program delivered in partnership with their key customer. They have developed a training academy on site with a capability centre within the factory environment. Learning and engagement is also encouraged through bite-sized learning; lunch & learns and line-side development.

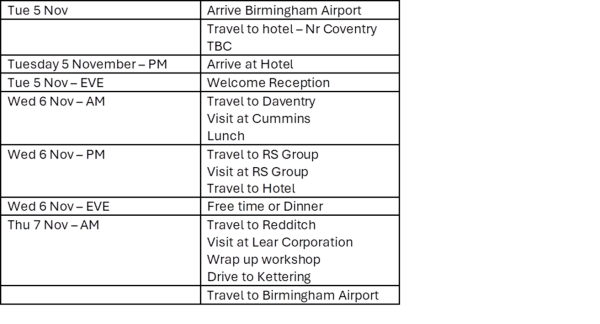

The Schedule for the 3 days is :